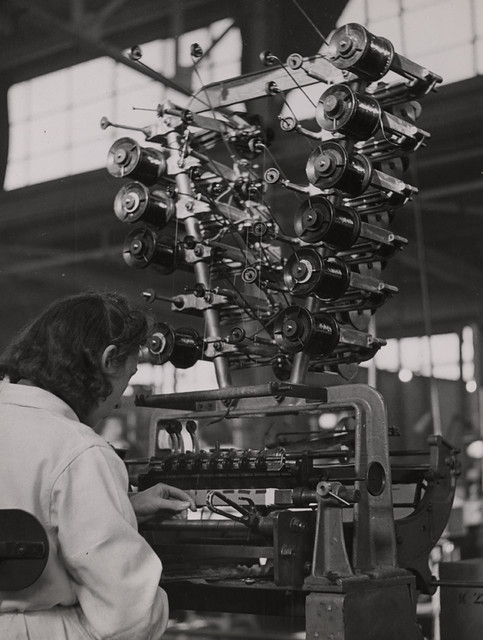

a bessemer converter at dorman long

-

Description

Teesside Steelworks at Warrenby founded by Dorman Long in 1917 and the ICI Wilton chemical works of the post-war era. The steel produced at Dorman Long was used to build the Sydney Harbour Bridge, Tyne Bridge, Auckland Harbour Bridge and many others. Today steel is made further west at the Corus BOS plant in Lackenby, using iron produced at the company's Redcar blast furnace, the largest in Europe. Both sites became part of Tata Steel when Corus was taken over in 2007, but as of February 2008, they still trade under the Corus name. However, these operations were recently ended. Bessemer process The Bessemer process was the first inexpensive industrial process for the mass-production of steel from molten pig iron prior to the open hearth furnace. The process is named after its inventor, Henry Bessemer, who took out a patent on the process in 1855. The process was independently discovered in 1851 by William Kelly.[1][2] The process had also been used outside of Europe for hundreds of years, but not on an industrial scale.[3] The key principle is removal of impurities from the iron by oxidation with air being blown through the molten iron. The oxidation also raises the temperature of the iron mass and keeps it molten. Details Bessemer converter components. Oxidation The oxidation process removes and skims off impurities such as silicon, manganese, and carbon in the form of oxides. These oxides either escape as gas or form a solid slag. The refractory lining of the converter also plays a role in the conversion—the clay lining is used in the acid Bessemer, in which there is low phosphorus in the raw material. Dolomite is used when the phosphorus content is high in the alkaline Bessemer (limestone or magnesite linings are also sometimes used instead of dolomite)—this is also known as a Gilchrist-Thomas converter, named after its inventor, Sidney Gilchrist Thomas. In order to give the steel the desired properties, other substances could be added to the molten steel when conversion was complete, such as spiegeleisen (an iron-carbon-mangane alloy). Managing the process When the required steel has been formed, it is poured out into ladles and then transferred into moulds while the lighter slag is left behind. The conversion process called the "blow" is completed in around twenty minutes. During this period the progress of the oxidation of the impurities is judged by the appearance of the flame issuing from the mouth of the converter: the modern use of photoelectric methods of recording the characteristics of the flame has greatly aided the blower in controlling the final quality of the product. After the blow, the liquid metal is recarburized to the desired point and other alloying materials are added, depending on the desired product. A Bessemer converter can treat a heat (batch of hot metal) of 5 to 30 tonnes at time. They usually are operated in pairs; one being blown while another being filled or tapped. Predecessor processes Bessemer converter at Station Square, Pittsburgh. Before the Bessemer process, Britain had no practical method of reducing the carbon content of pig iron. Steel was manufactured by the reverse process of adding carbon to carbon-free wrought iron, usually imported from Sweden. The manufacturing process, called cementation process, consisted of heating bars of wrought iron together with charcoal for periods of up to a week in a long stone box. This produced blister steel. Up to 3 tons of expensive coke was burnt for each ton of steel produced. Such steel when rolled into bars was sold at £50 to £60 (approximately £3,390 to £4,070 in 2008)[4] a long ton. The most difficult and work-intensive part of the process, however, was the production of wrought iron done in finery forges in Sweden. This process was refined in the 18th century with the introduction of Benjamin Huntsman's crucible steel-making techniques, which added an additional three hours firing time and required additional large quantities of coke. In making crucible steel the blister steel bars were broken into pieces and melted in small crucibles each containing 20 kg or so. This produced higher quality crucible steel but increased the cost. The Bessemer process reduced the time needed to make steel of this quality to about half an hour while requiring only the coke needed to melt the pig iron initially. The earliest Bessemer converters produced steel for £7 a long ton, although it initially sold for around £40 a ton. History Bessemer converter, Kelham Island Museum, Sheffield, England (2010). In 1740 Benjamin Huntsman developed the crucible technique for steel manufacture, at his workshop in the district of Handsworth in Sheffield. This process had an enormous impact on the quantity and quality of steel production. Sir Henry Bessemer described the origin of his invention in Chapters 10 and 11 of his autobiography. According to this book at the time of the outbreak of the Crimean War many English industrialists and inventors became interested in military technology and Bessemer himself developed a method for grooving artillery projectiles so that they could spin without the use of rifling in the bore of the gun. He patented this method in 1854 and began developing it in conjunction with the government of France. After a successful day of testing of his method at the Polygon in France he had a conversation with Claude-Étienne Minié who stated that a key barrier to the use of the larger, heavier spinning projectiles would be the strength of the gun and in particular "...he [Minié] did not consider it safe in practice to fire a 30-lb. shot from a 12-pounder cast-iron gun. The real question, he said, was; Could any guns be made to stand such heavy projectiles?".[clarification needed] This is what started Bessemer thinking about steel. At the time steel was difficult and expensive to make and was consequently used in only small items like cutlery and tools. Starting in January 1855 he began working on a way to produce steel in the massive quantities required for artillery and by October he filed his first patent related to the Bessemer process. According to his autobiography Bessemer was working with an ordinary reverbatory furnace but during a test, some pieces of pig iron were jostled off the side of the ladle, and were left above the ladle in the furnace's heat. When Bessemer went to push them into the ladle, he found that they were steel shells: the hot air alone had converted the outsides of the iron pieces to steel. This crucial discovery led him to completely redesign his furnace so that it would force high-pressure air through the molten iron using special air pumps. Intuitively this would seem to be folly because it would cool the iron. Instead, the oxygen in the forced air ignited silicon and carbon impurities in the iron, starting a positive feedback loop. As the iron became hotter, more impurities burned off, making the iron even hotter and burning off more impurities, producing a batch of hotter, purer, molten iron, which converts to steel more easily. Henry Bessemer Bessemer licensed the patent for his process to four ironmasters, for a total of £27,000, but the licensees failed to produce the quality of steel he had promised—it was "rotten hot and rotten cold", according to his friend, William Clay—and he later bought them back for £32,500. His plan had been to offer the licenses to one company in each of several geographic areas, at a royalty price per ton that included a lower rate on a proportion of their output in order to encourage production, but not so large a proportion that they might decide to reduce their selling prices. By this method he hoped to cause the new process to gain in standing and market share. He realised that the technical problem was due to impurities in the iron and concluded that the solution lay in knowing when to turn off the flow of air in his process so that the impurities were burned off but just the right amount of carbon remained. However, despite spending tens of thousands of pounds on experiments, he could not find the answer.[7] Certain grades of steel are sensitive to the 78% nitrogen which was part of the air blast passing through the steel. The solution was first discovered by English metallurgist Robert Forester Mushet, who had carried out thousands of experiments in the Forest of Dean. His method was to first burn off, as far as possible, all the impurities and carbon, then reintroduce carbon and manganese by adding an exact amount of spiegeleisen. This had the effect of improving the quality of the finished product, increasing its malleability—its ability to withstand rolling and forging at high temperatures and making it more suitable for a vast array of uses. The first company to license the process was the Manchester firm of W & J Galloway, and they did so before Bessemer announced it at Cheltenham in 1856. They are not included in his list of the four to whom he refunded the license fees. However, they subsequently rescinded their license in 1858 in return for the opportunity to invest in a partnership with Bessemer and others. This partnership began to manufacture steel in Sheffield from 1858, initially using imported charcoal pig iron from Sweden. This was the first commercial production. Patent battles Patents of such value did not escape criticism, and invalidity was urged against them on various grounds.[clarification needed] But Bessemer was able to maintain them intact without litigation, though he found it advisable to buy up the rights of one patentee,[who?] and in the case of Mushet was assisted by the patent being allowed to lapse in 1859 through non-payment of fees. Mushet's procedure was not essential and Bessemer proved this in 1865 by exhibiting a series of steel samples made using his process alone, but the value of the procedure was shown by its near universal adoption in conjunction with the Bessemer process. Whether or not Mushet's patents could have been sustained is not known, but in 1866 Robert Mushet's 16-year-old daughter travelled to London to confront Henry Bessemer at his offices, arguing that Bessemer's success was based on the results of her father’s work. Bessemer decided to pay Mushet an annual pension of £300, a very considerable sum, which he paid for 25 years. In 1866, Bessemer also provided finance for Zerah Colburn, the American locomotive engineer and journalist, to start a new weekly engineering newspaper called Engineering based in Bedford Street, London. It was not until many years later that the name of Colburn's benefactor was revealed. Prior to the launch of Engineering, Colburn, through the pages of The Engineer, had given support to Bessemer's work on steel and steelmaking. Bessemer furnace in operation in Youngstown, Ohio, 1941. The Bessemer process revolutionized steel manufacture by decreasing its cost, from £40 per long ton to £6–7 per long ton, along with greatly increasing the scale and speed of production of this vital raw material. The process also decreased the labor requirements for steel-making. Prior to its introduction, steel was far too expensive to make bridges or the framework for buildings and thus wrought iron had been used throughout the Industrial Revolution. After the introduction of the Bessemer process, steel and wrought iron became similarly priced, and most manufacturers turned to steel. Some claim the availability of cheap steel allowed large bridges to be built and enabled the construction of railroads, skyscrapers, and large ships;[12] however, the largest ship of the 19th century was the iron SS Great Eastern launched in 1858, high pressure steam-powered locomotive railways appeared in 1825 with the opening of the Stockton and Darlington railway (the first passenger railway opened in 1830 between Liverpool and Manchester), and the first modern large suspension bridge was the Menai Suspension Bridge completed in 1826: the later two decades before mass produced steel. Other important steel products—also made using the open hearth process—were steel cable, steel rods and sheet steel which enabled large, high-pressure boilers and high-tensile strength steel for machinery which enabled much more powerful engines, gears and axles than were possible previously. With large amounts of steel it became possible to build much more powerful guns and carriages, tanks, armored fighting vehicles and naval ships. Industrial steel also made possible the building of giant turbines and generators thus making the harnessing of water and steam power possible. The introduction of the large scale steel production process paved the way to mass industrialisation as observed in the 19th–20th centuries.[citation needed] However, as early as 1895 in the UK it was being noted that the heyday of the Bessemer process was over and that the open hearth method predominated. The Iron and Coal Trades Review said that it was "in a semi-moribund condition. Year after year, it has not only ceased to make progress, but it has absolutely declined." It has been suggested, both at that time and more recently, that the cause of this was the lack of trained personnel and investment in technology rather than any intrinsic to the process itself.[13] For example, one of the major causes of the decline of the giant ironmaking company Bolckow Vaughan of Middlesbrough was its failure to upgrade its technology.[14] The basic process, Thomas-Gilchrist process, remained longer in use, especially in the Continental Europe, where iron ores were of high phosphorus content [2] and open hearth process was not able to remove all phosphorus; almost all inexpensive construction steel in Germany was produced with this method in the 1950s and 1960s [3]. It was eventually superseded by basic oxygen steelmaking. Obsolescence In the U.S., commercial steel production using this method stopped in 1968. It was replaced by processes such as the basic oxygen (Linz-Donawitz) process, which offered better control of final chemistry. The Bessemer process was so fast (10–20 minutes for a heat) that it allowed little time for chemical analysis or adjustment of the alloying elements in the steel. Bessemer converters did not remove phosphorus efficiently from the molten steel; as low-phosphorus ores became more expensive, conversion costs increased. The process permitted only limited amount of scrap steel to be charged, further increasing costs, especially when scrap was inexpensive. Use of electric arc furnace technology competed favourably with the Bessemer process resulting in its obsolescence. Basic oxygen steelmaking is essentially an improved version of the Bessemer process (decarburization by blowing oxygen as gas into the heat rather than burning the excess carbon away by adding oxygen carrying substances into the heat). The advantages of pure oxygen blast over air blast was known to Henry Bessemer, but the 19th century technology was not advanced enough to allow for the production of the large quantities of pure oxygen to make it economically feasible for use. -

Owner

sean@bradford -

Source

Flickr (Flickr) -

License

What does this mean? All Rights Reserved (Seek permission to reuse)

-

Further information

Link: https://www.flickr.com/photos/64261287@N08/7581895600/

Resource type: Image

Added by: Simon Cotterill

Last modified: 9 years, 1 month ago

Viewed: 2855 times

Picture Taken: Unknown -

Co-Curate tags